beverage industry

Gekoplast designs packaging solutions for the glass packaging and beverage industries, where hygiene, product protection, and delivery time are crucial to success.

Gekoplast: Specialized packaging solutions for the glass packaging and beverage industries

The beverage and glass packaging sectors are industries where hygiene, product protection, and timely delivery play a vital role. Gekoplast has undertaken taken this challenge by designing and developing specialized packaging solutions tailored to the specific requirements of these sectors. Through close collaboration with skilled operators, we have created reliable packaging systems for beverage containers—whether they are glass bottles, plastic bottles, cans, or related accessories such as caps and preforms, Gekoplast always has an optimal, ready-to-use solution.

Layer pad: Gekoplast’s flagship product

One of Gekoplast’s most recognized products in the beverage industry is the plastic layer pad made of Kartonplast. This product has earned Gekoplast international recognition. The layer pad provides excellent load protection and stability, minimizing the risk of damage during transport.

Comprehensive logistics solutions

We also offer a wide range of complementary logistics solutions, designed to facilitate the transport of bottles and cans while ensuring optimal protection and product safety. These include:

Plastic pallets – durable, hygienic, and easy to clean

Slip sheets – ideal for securing layers of goods

Trays – providing additional stability

Foldable containers – saving space during storage and transport

Reusable Layer Pads

Layer pads are widely used in the beverage industry as interlayer separators for glass bottles, plastic bottles, and cans. Made of polypropylene, these separators enable efficient transport and facilitate the palletization process, significantly reducing packaging costs.

Eco-friendly and Reusable

Our layer pads are designed according to circular economy principles. These are durable, high-quality products that can be reused multiple times. Moreover, at the end of their lifecycle, they are 100% recyclable and can be reprocessed into new products at our facility.

Stability and Safety

Layer pads made of Kartonplast or solid polypropylene sheets ensure the stability and safety of loaded pallets during transportation. We supply them in standard pallet sizes, but also offer custom-made solutions tailored to specific customer needs, including non-standard dimensions.

Details:

Rounded corners – Prevent tearing of protective pallet film

Sealed edges – Improve hygiene and ease of cleaning

Custom options – Size, corner radius, and color customization available

Layer pads made of corrugated PP (Kartonplast®):

- Thickness: from 2 to 12 mm

- Weight: from 250 to 3000 g/m²

- Our best-selling solution for the glass industry

Layer pads made of solid sheet (Eplak®):

- 0.8 mm thickness – Ideal for transporting cans and jars

- 3 mm thickness – Durable solution for heavier glass, e.g. wine bottles

- 4.2 mm thickness – Recommended for transporting the heaviest loads

Latest Development:

Layer Pads for the Cosmetics Industry

Our latest innovation is a custom-designed layer pad for the logistics of glass jars in the cosmetics sector. Featuring a special high-friction surface, it prevents products from slipping during transport, ensuring maximum safety.

Why choose Gekoplast layer pads?

- Eco-conscious – Products aligned with sustainable development principles

- Versatile – Available in standard and custom dimensions

- Safe – Guaranteed stability and protection of your goods

- Innovative – Modern solutions tailored to industry-specific needs

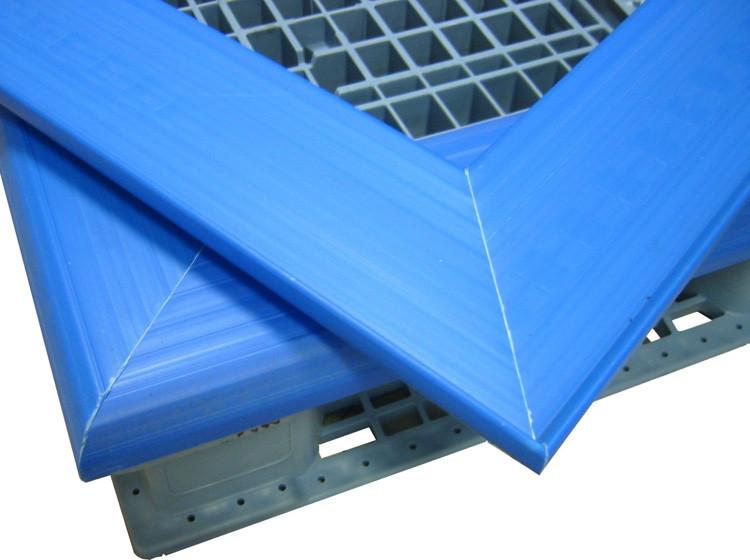

Top Frames and Phyl Pallets

Top frames are structural components used to stabilize bulk shipments such as glass bottles, jars, plastic bottles, and metal cans.

They are typically used in combination with our layer pads and Phyl pallets, which together ensure secure and efficient stabilization of product loads by protecting individual layers.

Made from polypropylene—a highly recyclable polymer—these top frames are designed to prevent damage to stretch film during wrapping.

Thanks to their durability and reusability, they significantly reduce logistics costs while ensuring safe transport.

Phyl pallets are particularly recommended for the beverage industry due to their unique properties. Made from inorganic material, they are resistant to mold, fungi, and bacteria.

Unlike wooden pallets, they do not require fumigation and are easy to clean before reuse, making them an ideal solution for demanding industrial environments.

Why choose Phyl pallets?

- Durability: Plastic pallets are up to

20 times more durable than traditional wooden pallets. Their dimensions and shape remain consistent throughout their service life. - Safety: Mechanical properties and load-bearing strength are tested in accordance with UNI/ISO 8611 standards, ensuring top quality and reliability.

- Eco-Friendly: Made from recyclable polypropylene, Phyl pallets support sustainability and circular economy principles.

- Hygiene: Easy to clean andmoisture-resistant, they are ideal for industries with strict hygiene requirements.

Octabins

Octabins are an eco-friendly and cost-effective alternative to traditional metal or wooden bulk containers. Designed with efficiency and sustainability in mind, they consist of three main components: a base, a foldable sleeve, and a lid. This structure allows octabins to be manually assembled in just a few seconds, making them extremely user-friendly.

The octagonal shape ensures smooth integration with existing production lines and automation systems, enhancing process efficiency.

Manufactured from our PP Kartonplast corrugated sheet, octabins are both lightweight and durable. This unique combination reduces the overall load weight, leading to lower transport costs and a significant reduction in CO₂ emissions.

When empty or in storage, octabins can be folded flat to save valuable space. We offer both standard pallet sizes and the option to produce custom dimensions tailored to individual customer needs.

Additionally, we provide custom printing options to label octabins according to client specifications.

Octabins are strong, durable, and reusable, making them a sustainable choice for your packaging needs. They can be used with or without liners, and their smooth surface makes them easy to clean and maintain.

For industries dealing with plastic caps or bottle closures, we offer octabins with a bottom dispensing hole, a commonly preferred release system in such applications, providing both efficiency and convenience.

Advantages:

- Environmentally friendly and economical

- Lightweight yet durable construction

- Reduce transport costs and CO₂ emissions

- Space-saving due to flat storage

- Customizable in size and print

- Reusable, durable, and easy to clean

- Specialized solutions for specific industries